TSMC will break ground on its 1.4nm (A14 process) facility in Taichung by the end of 2025, but won’t use ASML’s expensive High-NA EUV machines. The chip giant believes existing Low-NA EUV technology combined with internal innovations provides sufficient scaling for this next-generation node.

TSMC 1.4nm A14 Process: Timeline & Specs

| Detail | Information |

|---|---|

| Process Node | A14 (1.4nm class) |

| Facility Location | Taichung, Taiwan |

| Groundbreaking | End of 2025 |

| Mass Production | Second half of 2028 |

| Lithography | Low-NA EUV (no High-NA) |

| Performance Gain | 15% improvement vs 2nm |

Why Skip High-NA EUV?

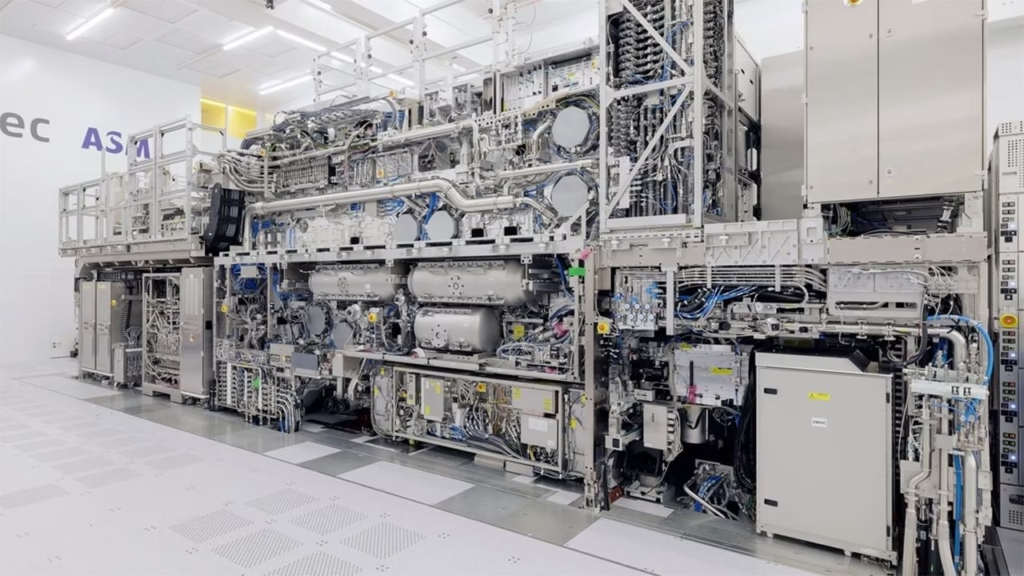

TSMC confirmed it won’t use High-NA EUV lithography for A16 and A14 processes, as Low-NA EUV tools combined with internal innovations provide sufficient scaling and performance benefits. This strategy prioritizes cost-efficiency—High-NA EUV systems cost around $350 million each and require specialized facilities.

From 2nm to A14, TSMC maintains similar processing step complexity without High-NA while achieving competitive results. This approach gives TSMC flexibility while competitors like Intel rush to adopt the expensive technology.

Production Timeline & Investment

Construction begins in Taichung by end of 2025, with mass production not expected before second half of 2028. The A14 node promises 15% performance improvement and 30% power efficiency gains over current nodes, making it attractive for flagship processors and AI chips.

For official announcements, check TSMC’s technology updates for process node roadmaps.

Explore more semiconductor insights on our chip technology guide covering industry developments.

Intel and Samsung Take Different Path

While TSMC sticks with Low-NA EUV, Intel already installed High-NA systems at its Oregon facility, and Samsung is expected to follow. This creates an interesting competitive dynamic where different approaches target the same performance goals.

The Bottom Line: TSMC’s decision to skip High-NA EUV for 1.4nm demonstrates confidence in its existing technology stack. By avoiding $350 million machines, TSMC maintains cost advantages while delivering competitive performance improvements by 2028.

FAQs

When will TSMC start making 1.4nm chips?

Mass production begins in the second half of 2028 after groundbreaking in late 2025.

Why is TSMC avoiding High-NA EUV technology?

TSMC believes Low-NA EUV with internal innovations achieves similar results at lower cost.