Tesla CEO Elon Musk has confirmed a groundbreaking partnership with Samsung to manufacture next-generation AI chips, revealing the deal’s value far exceeds the reported $16.5 billion figure.

Tesla’s Samsung Chip Deal: Beyond the Headlines

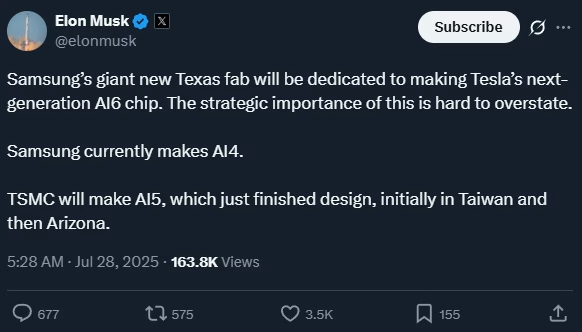

The partnership marks a significant win for Samsung’s foundry division, which has struggled to compete with Taiwan’s TSMC in recent years. Musk personally confirmed on X (formerly Twitter) that Samsung will produce Tesla’s AI6 chips at their Taylor, Texas facility.

Key Deal Details

| Aspect | Details |

|---|---|

| Deal Value | $16.5B+ (Musk says “several times higher”) |

| Location | Samsung’s Taylor, Texas facility |

| Chips | AI6 (next-gen) by Samsung, AI5 by TSMC |

| Timeline | AI5 volume production by end of 2025 |

| Process | 3-nanometer technology |

What Makes This Partnership Special

Unlike typical chip manufacturing agreements, Tesla will actively assist Samsung in optimizing production efficiency. Musk emphasized he’ll “walk the line personally” to accelerate progress, leveraging the facility’s proximity to his Texas residence.

The AI6 chips represent more than just automotive processors—they’re designed as a unifying platform for both Tesla vehicles and Optimus humanoid robots. Early reports suggest these chips could perform up to 2,500 trillion operations per second.

Strategic Impact on Tesla’s Future

This deal addresses Tesla’s ongoing hardware upgrade challenges. Current AI3 chips in older vehicles struggle with the latest Full Self-Driving (FSD) updates, making the AI5 and AI6 generations crucial for autonomous driving capabilities.

While TSMC continues manufacturing AI5 chips in Taiwan and Arizona, Samsung’s involvement ensures Tesla has multiple suppliers for its critical AI infrastructure—a smart move given global chip supply chain vulnerabilities.

FAQs

When will Tesla’s new AI chips be available in vehicles?

AI5 chips are expected in volume production by end of 2025, with AI6 following later.

Why is Tesla working with both Samsung and TSMC?

This dual-supplier strategy reduces dependency and ensures uninterrupted chip supply for Tesla’s growing needs.