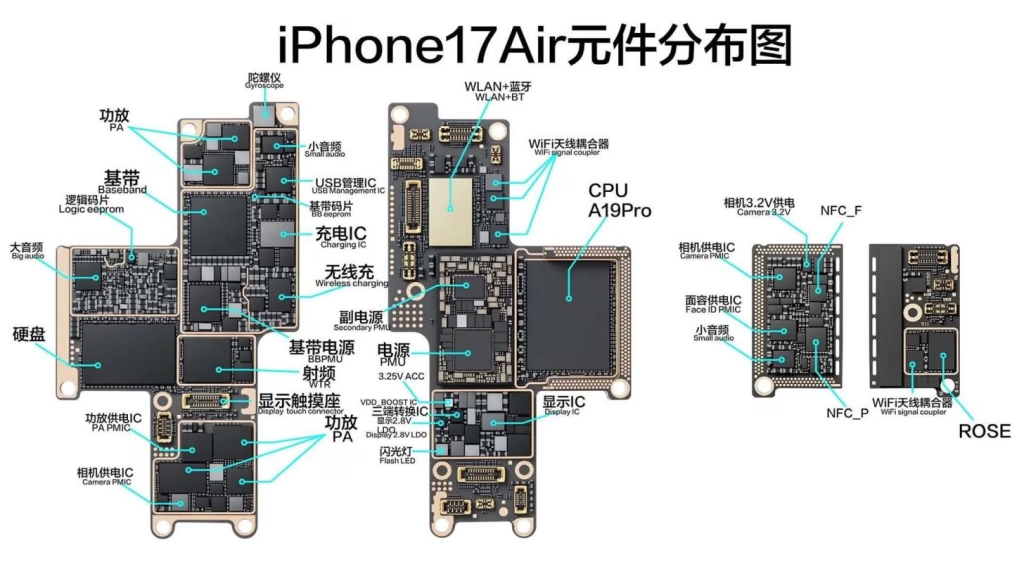

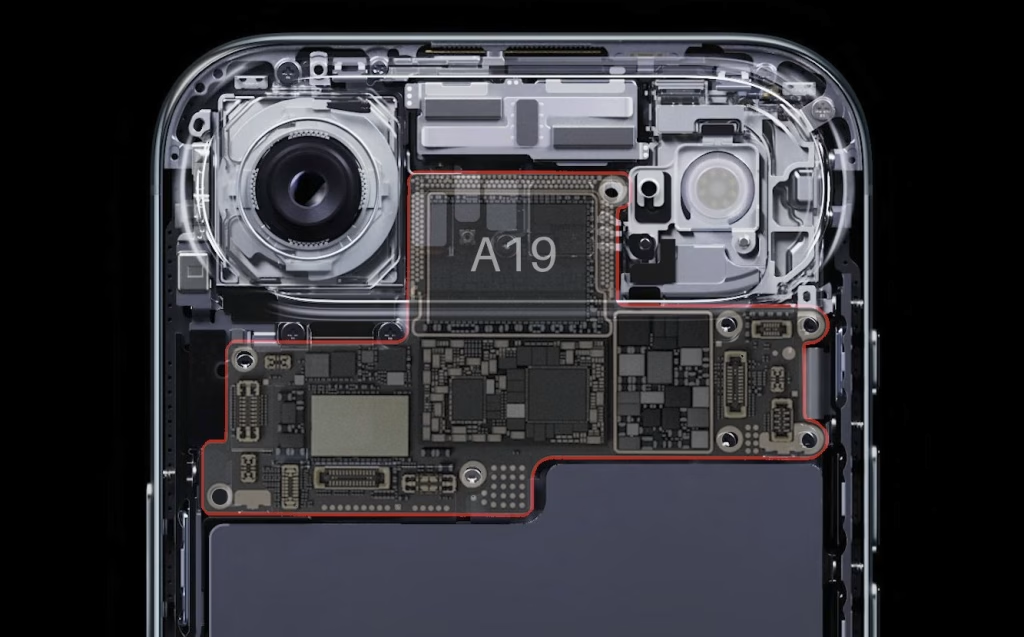

Apple‘s iPhone Air has achieved the impossible—packing Pro-level performance into a 5.6mm chassis that’s the thinnest iPhone ever. New revelations about the device’s logic board arrangement show that only the A19 Pro die area is housed inside the camera bump, contrary to initial assumptions about the entire PCB placement.

Revolutionary Logic Board Design

The iPhone Air features the A19 Pro chip inside, making it the thinnest iPhone with Pro-level processing power. The internal arrangement demonstrates Apple’s engineering prowess in maximizing space efficiency while maintaining thermal performance.

| Internal Components | Placement Strategy | Engineering Benefit |

|---|---|---|

| A19 Pro Die | Inside camera bump only | Optimal heat dissipation |

| Logic Board PCB | Distributed in main chassis | Maintains thinness |

| Camera Bump Height | Strategic component housing | Space optimization |

| Overall Thickness | 5.6mm | Thinnest iPhone ever |

Camera Bump Serves Dual Purpose

The camera bump isn’t just for optical components—it cleverly houses the most heat-generating part of the logic board. This placement allows the A19 Pro die to have dedicated thermal management while keeping the main chassis ultra-thin.

Engineering Trade-offs Revealed

The iPhone Air’s extreme thinness comes with battery compromises, but Apple’s logic board engineering minimizes other sacrifices. By strategically placing only the processor die in the camera bump, Apple maintains full functionality in an impossibly thin form factor.

A19 Pro Performance in Ultra-Thin Design

Despite the thin profile, the iPhone Air packs Pro-level chip performance and promises long battery life in an ultra-durable design. The logic board arrangement enables this seemingly contradictory combination of thinness and power.

Comparison with Previous iPhones

Traditional iPhone designs use stacked logic boards or dual-layer configurations for space efficiency. The iPhone Air’s approach represents a new paradigm where critical components get dedicated housing while maintaining overall device thinness.

6.5-inch Display in Minimal Chassis

The iPhone Air features a substantial 6.5-inch display despite its minimal thickness. The logic board design enables this screen-to-body ratio by maximizing every millimeter of internal space.

Manufacturing Complexity

This logic board arrangement likely increases manufacturing complexity and costs, but demonstrates Apple’s commitment to pushing design boundaries. The precise placement of the A19 Pro die requires advanced thermal engineering and assembly techniques.

Market Impact and Future Implications

The iPhone Air’s internal design could influence future smartphone architecture. As manufacturers chase ever-thinner profiles, Apple’s camera bump utilization strategy provides a roadmap for maintaining performance without compromising form factor.

This engineering approach validates that extreme thinness doesn’t necessarily mean compromised functionality when components are strategically arranged.

FAQs

Does the camera bump placement affect iPhone Air performance?

No, strategic A19 Pro die placement in the bump actually improves thermal management.

Will this design approach appear in other iPhones?

Apple hasn’t announced plans, but this engineering could influence future ultra-thin models.